Warhol Museum - Storefront Display

March 2021 - June 2021

The Andy Warhol Museum was contracted by the UCCA Center for Contemporary Art to assemble an exhibit for their locations in Beijing and Shanghai. As part of this installation, it was requested that the Warhol Museum construct a replica of one of Andy Warhol’s storefront window displays which he originally produced for the Bonwit Teller department store in New York City in 1955. Sadly, none of these advertisements survived to the modern day, but two other replica storefronts have been created: “Bonwit Loves Replique” and “Bonwit and Miss Dior”. This third replica, “Bonwit Loves Mistigri,” would accompany “Bonwit Loves Replique” to the Shanghai and Beijing exhibitions.

https://ucca.org.cn/en/exhibition/andy-warhol/

Design for the storefront began with assembling documentation of Warhol’s work from that time. Thankfully, the artist himself—often described as a ‘packrat’—kept thousands of documents, ephemera, and even garbage in his 'time capsules’. These numbered cardboard boxes, often filled with nothing more than detritus, are a crucial part of the Andy Warhol Museum’s collection, as their contents allows greater insight into the artist’s process and inspirations.

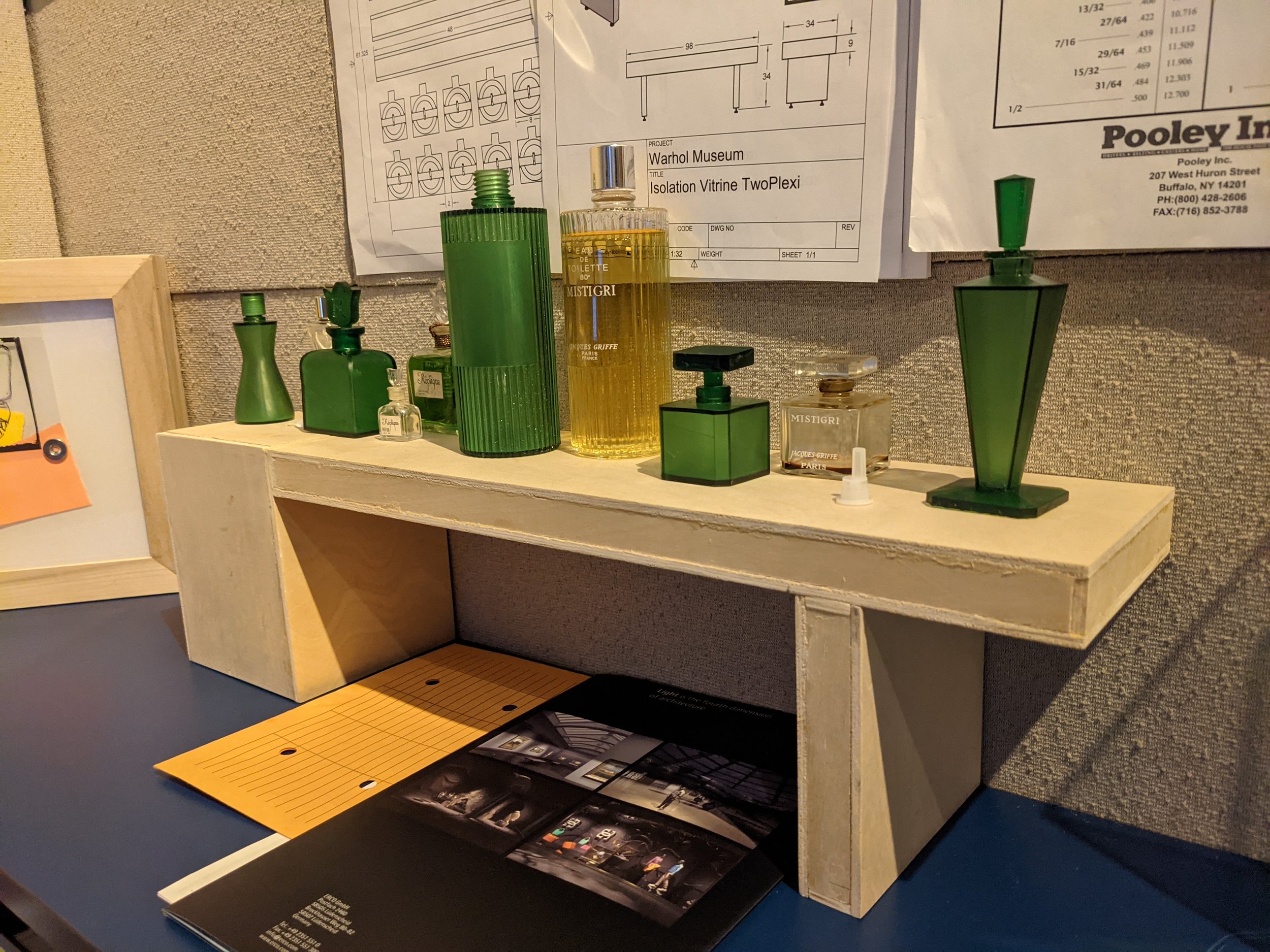

The Bonwit Teller storefront displays advertised luxury perfume brands, but due to import restrictions on commodity goods, we would be unable to include the original bottles with our shipment. This created an opportunity to create replicas of all the bottles, as well as designs which were absent from the collection or which we were unable to source.

The bottles were replicated with by creating 3D models in a ‘computer aided design’ program (Fusion 360) and printed on a SLA Resin 3D printer.

Dimensions were taken from the glass perfume bottles when it was possible to source the genuine article; others were derived from advertising and historical photography when acquiring an original was impossible or cost-prohibitive.

The original displays also included stationery and other printed elements that needed to be replicated as part of this display, including a box of unknown purpose. From historical documents, we were able to source the original illustrations but not the purpose of the box. A number of variations were made.

Historical sources point to the original storefront displays being created from fence pickets. Construction lumber served as a reasonable modern alternative. The panels were stained to match the existing “Bonwit Loves Replique” display.

A number of functional elements were added to the reverse of the storefront to assist in assembly and alignment. Shelves were added to hold each of the bottles within the holes cut in the panel fronts.

Pittsburgh-based artist Sandy Kessler Kaminski was commissioned to replicate the illustration present on the historical storefront advertisements. She worked with a similar chalk and oil pastel process that was analogous to the processes used on the original work.

The final illustrations were sealed with a water-based topcoat to protect the artwork during transportation and display.

The final 3D prints of the bottles were finished with a layer of gloss UV-resistant clear-coat to create the appropriate glass-like appearance. Afterwards, they were filled with dyed epoxy resin to simulate the original liquid perfumes.

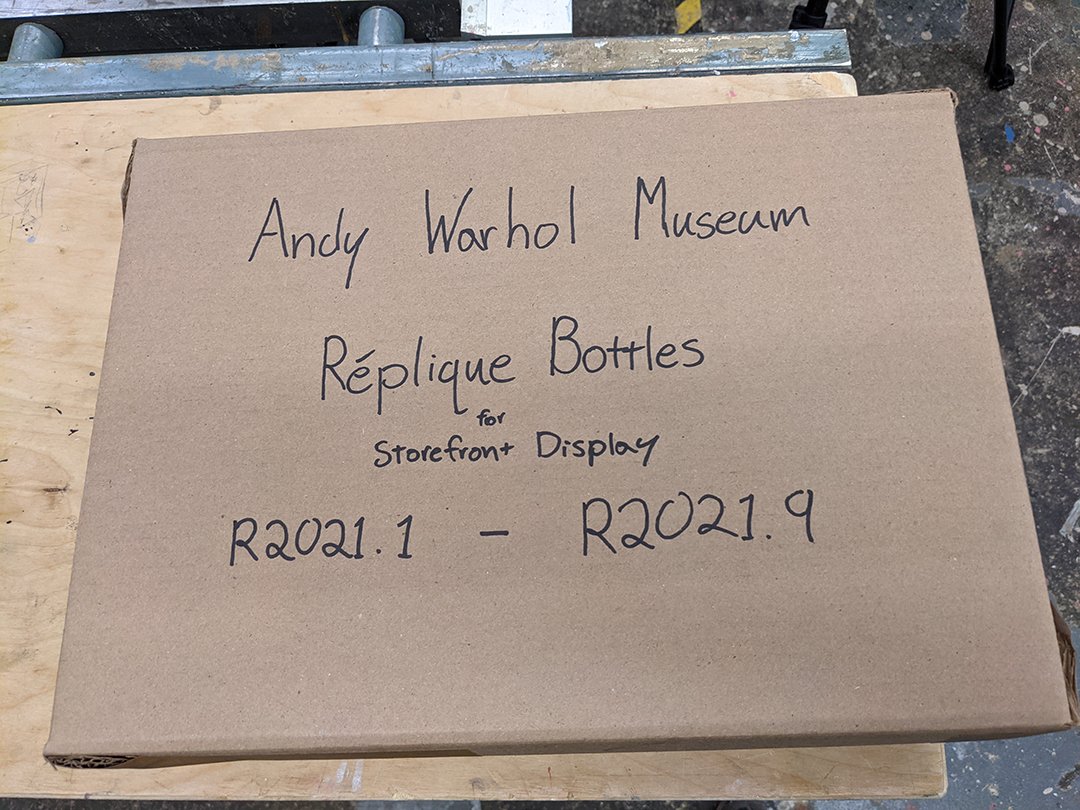

The bottle were packed for transit in foam coated with Tyvek. Because these reproductions are not made with archival materials the greatest concern was them becoming damaged in transit.

The storefront then traveled to two venues in China and traveled again in 2025 to a new international exhibit.